In today’s fast-paced workplaces, safety and efficiency go hand in hand. One of the most overlooked—but most important—skills is manual handling. Whether it’s lifting, carrying, pushing, or pulling, these everyday tasks play a huge role in protecting workers’ health and ensuring productivity. Yet, improper techniques continue to cause injuries worldwide, making manual handling a priority for businesses in 2025.

Why Manual Handling Still Matters in 2025

Every day, millions of workers across industries—from construction and warehousing to healthcare and even office environments—perform manual handling tasks. Whether it’s lifting boxes, moving furniture, assisting patients, or carrying equipment, these seemingly simple actions can pose serious risks if done incorrectly.

According to European Agency for Safety and Health at Work, manual handling is still one of the top causes of workplace injuries. Nearly one-third of musculoskeletal disorders worldwide are linked to poor lifting and carrying techniques. Even in 2025, as technology reshapes how we work, the importance of safe manual handling practices remains critical.

What Is Manual Handling?

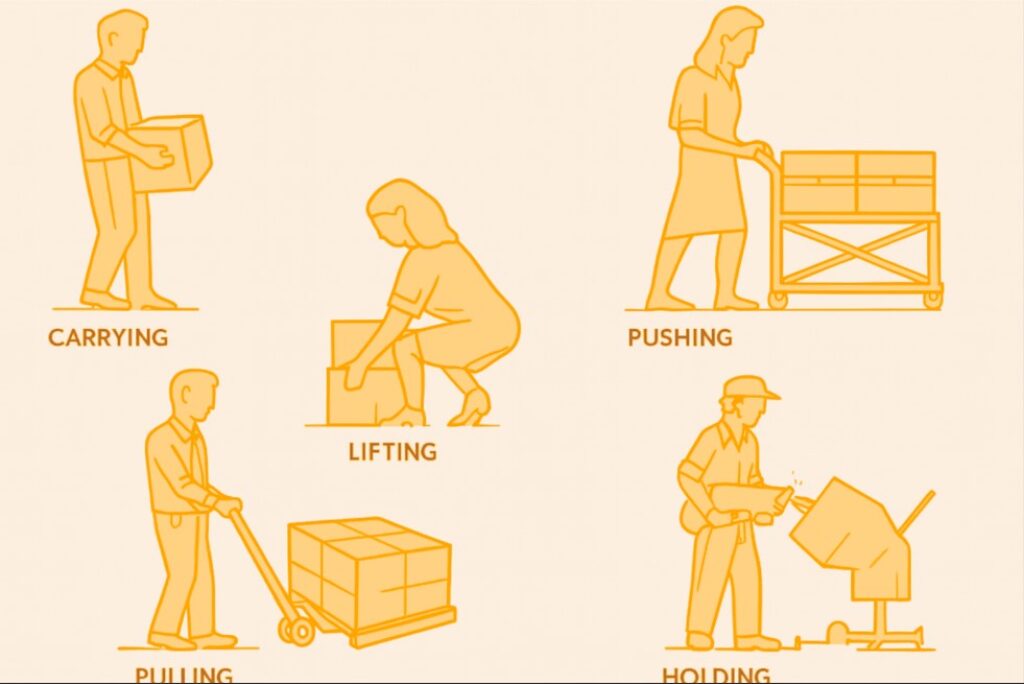

Manual handling refers to transporting or supporting a load by hand or bodily force. It includes activities such as:

- Lifting

- Carrying

- Lowering

- Pushing

- Pulling

A “load” may be an object, a person, or even an animal. In workplaces, it often means boxes, tools, or equipment. In healthcare, it may involve assisting patients or moving medical devices.

To learn the fundamentals in depth, see this Manual Handling Training Course.

Risks of Poor Manual Handling

Without proper technique, manual handling can cause:

- Back Injuries – Often linked to poor posture or overexertion.

- Musculoskeletal Disorders (MSDs) – Repetitive strain injuries that affect muscles, joints, and tendons.

- Slips, Trips, and Falls – Carrying heavy or awkward loads increases risk.

- Long-Term Health Issues – Including chronic pain, hernias, and joint damage.

For example, lifting a box with a bent back puts huge pressure on the spine, increasing the risk of slipped discs. The OSHA Manual Handling Guidelines emphasize proper posture as a key preventive measure.

Legal & Compliance Requirements in 2025

Employers must legally minimize manual handling risks. For example:

- UK: Manual Handling Operations Regulations (MHOR)

- EU: Directive 90/269/EEC on manual handling

- US: OSHA ergonomics standards

- Australia: Safe Work Australia Code of Practice

These frameworks stress risk assessments, staff training, and use of safe equipment. Companies that fail to comply risk fines, lawsuits, or reputational harm.

Best Practices for Manual Handling

Here are five core principles every worker should follow:

1. Assess the Load

- Check weight, size, and stability.

- Ask: Can I lift this safely on my own?

- If not, use assistance—equipment or teamwork.

2. Plan the Lift

- Clear the path of obstacles.

- Ensure there’s a safe place to set the load down.

3. Use Correct Lifting Technique

- Bend your knees, not your back.

- Keep the load close to your body.

- Avoid twisting while lifting.

- Keep feet stable and balanced.

4. Use Equipment

- Trolleys, pallet jacks, hoists, or conveyors can significantly reduce strain.

5. Teamwork

- For heavy or awkward items, use two or more people.

For advanced strategies and workplace-specific case studies, check out Advanced Manual Handling Safety Guide.

Common Workplace Scenarios

Manual handling affects nearly every industry:

- Construction: Moving bricks, cement bags, or tools.

- Warehousing: Lifting packages, stacking shelves.

- Healthcare: Patient transfers and equipment handling.

- Offices: Shifting files, IT hardware, or office furniture.

Each sector has unique risks, but the core handling principles remain universal.

The Employer’s Role in Manual Handling Safety

Employers have both a legal and moral duty to protect employees. Key responsibilities include:

- Conducting regular risk assessments

- Providing training programs and refresher courses

- Supplying ergonomic equipment and mechanical aids

- Encouraging employees to ask for help when needed

For instance, logistics companies often install conveyor belts, while hospitals invest in hoists for safer patient transfers.

The Employee’s Role in Staying Safe

Employees play a vital part by:

- Following training and applying correct techniques

- Reporting unsafe practices or faulty equipment

- Maintaining personal fitness (e.g., core strength, flexibility)

- Asking for help instead of risking injury

Technology and Manual Handling in 2025

Modern workplaces are adopting tech-driven safety solutions:

- Wearable Sensors – Track posture and issue real-time alerts.

- Exoskeletons – Provide mechanical support to reduce strain.

- AI-Powered Risk Assessments – Predict hazards before accidents occur.

- Automation & Robotics – Minimize human involvement in high-risk tasks.

Manual Handling Training: A Smart Investment

Structured training programs usually include:

- Anatomy of the spine and injury risks

- Demonstrations of safe lifting and carrying techniques

- Correct use of mechanical aids

- Real-world, workplace-specific case studies

CPD-accredited training has become the gold standard, ensuring employees gain both compliance knowledge and professional development benefits. If your team needs a refresher, our Manual Handling Training 2025 Course is a practical starting point.

Quick Safety Checklist

- Warm up before lifting heavy loads

- Wear footwear with proper grip

- Avoid carrying above chest level

- Break down loads into smaller parts

- Take regular breaks during repetitive handling tasks

Conclusion

Manual handling may look simple, but its impact on workplace health and productivity is significant. As we move through 2025, employers and employees must work together to prioritize safety, embrace technology, and foster a culture of care.

With the right planning, training, and equipment, organizations can reduce risks, protect their people, and build safer, more productive workplaces.

👉 Ready to improve safety in your workplace?

Start with This Course Manual Handling Training 2025 Course for essential foundations, or explore the Advanced Manual Handling Safety Guide for in-depth strategies.